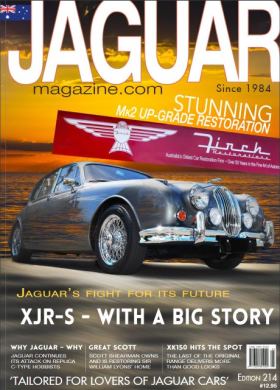

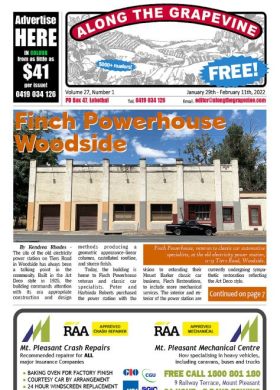

The Sentinel Lorry Restoration: Inside Finch Restorations’ Nine-Stage Process

As seen in our recent Facebook and Instagram posts, here’s a deeper look at how the Sentinel Lorry’s restoration is unfolding, stage by stage.

At Finch Restorations, each vehicle we work on follows a structured and proven approach. We’ve developed a nine-stage restoration system that allows us to tailor each project according to its needs — whether it’s a complete ground-up rebuild or focused work on specific systems or bodywork.

Some vehicles pass through all nine stages, from transport and disassembly through to final assembly and finishing. Others may only require selected stages — for example, structural repairs, a new paint job, or reassembly of previously restored components. This system enables us to accurately define scope, manage progress, and ensure that the restoration progresses in an efficient, transparent, and well-documented manner, regardless of the project’s size or complexity.

One of the vehicles currently going through the early stages of this system is a rare and remarkable Sentinel Diesel 8-Ton Lorry — believed to be the only surviving example in Australia and one of just 26 worldwide. Its restoration offers a great look at how the Finch process begins to unfold, stage by stage.

Stage 1T: Transport

The first step in the process is transport to our workshops, which can be arranged either by the owner or by Finch. In the Sentinel’s case, the vehicle was transported from Victoria.

Stage 1R: Receival

Upon arrival, the vehicle undergoes inspection, cataloguing, and evaluation. The Sentinel came with numerous parts in crates, all of which were sorted, photographed, and logged. The lorry itself was assessed for overall condition to guide the planning of future work.

Stage 2: Mock-Ups and Modifications

This stage focuses on creating physical templates or mock-ups to replicate damaged, missing, or misaligned components. For the Sentinel, this included the creation of templates to assist in reshaping or reproducing compromised body panels.

Stage 3: Disassembly

Depending on the project’s scope, this can range from partial disassembly to a full strip-down. In the Sentinel’s case, the process involved the full dismantling of the Cabin.

Stage 4: Paint Strip

At this point, the body is stripped back to bare metal through the removal of old paint and sealants, allowing for thorough inspection of rust, corrosion, and prior damage. The Sentinel is currently in this stage, having been sent off for paint removal.

These five stages represent only the beginning of the Sentinel’s journey, but they demonstrate the value of Finch’s structured approach. The stage system allows both the team and the client to clearly track progress and understand where the vehicle sits within the overall restoration.

Importantly, not all vehicles undergo every stage. Some may only require specific services — such as Stage 1B - Receival, Stage 5C - Chassis, Stage 5D - Drivetrain and Stage 5E - Electrical Systems— depending on the desired outcome.

The stages also form part of Finch’s broader project planning framework, which includes five key gateways:

- Vehicle Suitability – Is the vehicle a candidate for restoration?

- Restoration Route – What kind of restoration is being pursued?

- Scope Determination – What stages will be involved?

- Project Velocity – At what pace will the work progress?

- Parts Procurement – Who will source and supply the necessary parts?

By aligning a restoration with the stages and the gateways, we ensure each project is carefully tailored, realistically scoped, and deeply informed — from first transport to final polish.

Learn more about our restoration stages:

https://finchrestorations.com.au/our-restoration-system/gateway-3-restoration-scope

Or explore the full Gateway system that underpins our project planning:

https://finchrestorations.com.au/our-restoration-system