Custom Power Steering Fabrication for Jaguar Restoration Projects

When restoring or modifying classic vehicles, modern components don’t always play nicely with legacy systems — and that was exactly the case during a recent Jaguar project at Finch Restorations. In this instance, our team was tasked with adapting a US-spec power steering pump to work with a British Jaguar steering rack. The challenge? Mismatched threads and fittings, with no direct adapters available. Efforts to connect the Jaguar steering rack to the American power steering pump were hampered by incompatible imperial fittings from different regions. Local suppliers couldn’t provide a match, and no off-the-shelf solution was available from reference manuals or parts databases.

With no ready-made answer, custom fabrication was the only viable path forward:

Template Development:

Second-hand power steering pipes were sourced and carefully reshaped to determine the required hose sizes and routing.

Custom Pipework:

A new high-pressure pipe was fabricated. To solve the thread mismatch:

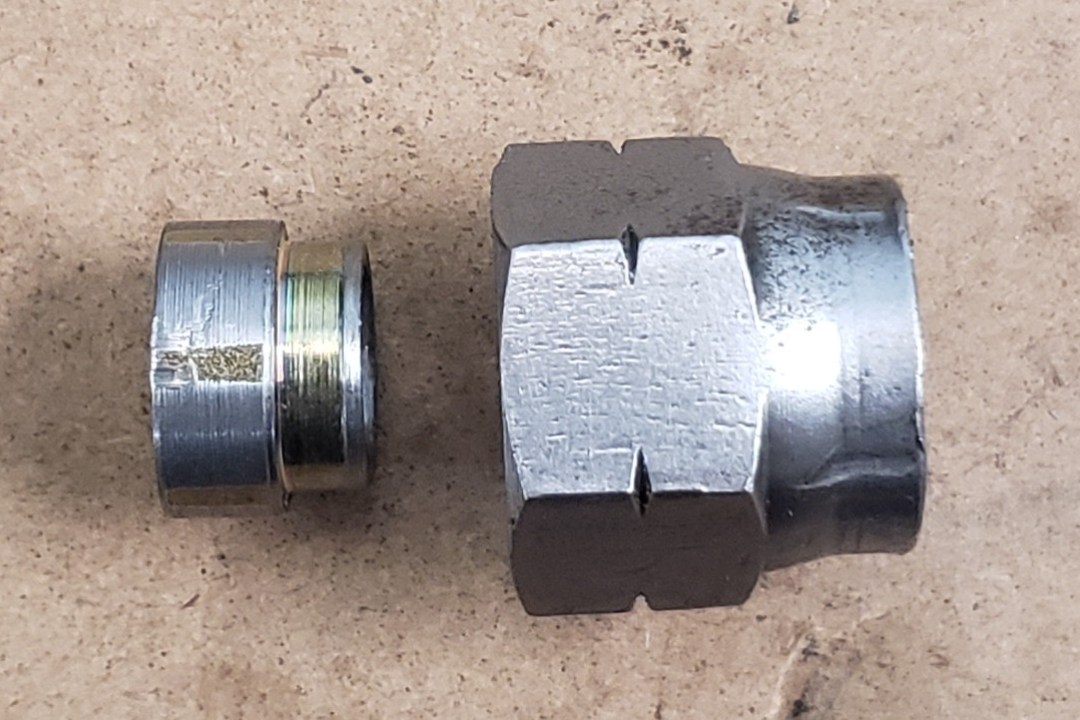

- A nut from an existing fitting was repurposed.

- A custom ferrule was machined to adapt the nut to the pipe being used.

- A flared nut was created to ensure a secure and leak-free connection.

Support and Mounting:

A custom bracket and clamp were fabricated to support the high-pressure pipe along the pump mounting point.

Fitting Machining:

Two additional custom fittings were machined in-house to resolve remaining mismatches between the hoses and system components.

Hose Assembly and Testing:

- The high-pressure hose was cut to length and flared.

- The return line was rerouted to match the new high-pressure line.

- The team confirmed adequate clearance to the bottom radiator and other surrounding systems.

Through precision machining, part repurposing, and careful planning, the team successfully created a functional and secure custom power steering solution. This approach not only overcame the thread incompatibility but ensured durability and serviceability moving forward — all while retaining the integrity of the vehicle's restoration.