About Finch Restorations – Australia’s Premier Classic Car Restoration Specialists

Australia's premier specialists in classic and vintage vehicle restorations.

For more than six decades, Finch Restorations has proudly held the title of Australia's most trusted name in the field of classic and vintage car restoration. Founded in 1965 by the esteemed craftsman Ray Finch, our unwavering commitment to preserving the rich tapestry of automotive history has garnered us recognition not just locally, but internationally. Our team of skilled artisans and restorers is dedicated to ensuring that each vehicle we work on is treated with the utmost care and respect. Today, we seamlessly blend traditional heritage techniques with the latest cutting-edge innovations, allowing us to restore iconic vehicles to their original splendour. Whether it’s a beloved classic or a rare vintage gem, we are passionate about bringing these automotive masterpieces back to life.

Our Story: Six Decades of Excellence, Growth & Evolution

1965. Founded in Mount Gambier

Ray Finch established a crash-repair shop, joined the local Veteran and Vintage Car Club, and began taking on restoration projects.

1970. Dedicated Classic Car Workshop

With increasing demand, Ray opened a new workshop focused exclusively on classic cars, serving clients in South Australia and Victoria.

1985. Move to the Adelaide Hills

Ray relocated to Echunga, where he partnered with Wayne Hocking, a talented antique furniture maker. They collaborated as Finch & Hocking while operating independent businesses. In 1989, Colin Higgs became Ray’s first full-time employee, and the growing business soon required larger premises.

1992. Expansion to Mount Barker

Ray and Wayne moved to adjoining workshops in a newly established industrial estate in Oborn Road, Mount Barker, marking a new phase of growth.

2000. Ray Finch’s Retirement

Ray stepped back from the business but continued his passion for car building from his home workshop.

2014. New Ownership

Seeking a career change from naval shipbuilding, Peter and Harbinda Roberts acquired Finch Restorations.

2016-2024. Growth & Innovation

- 2016: Expanded facilities at 17 Oborn Road, Mount Barker, and acquired the historic Woodside Power Station.

- 2019: Established Finch Powerhouse, incorporating former stock and assets from Kent Town Auto Tune.

- 2024: Became official Australian installer for Electrogenic EV conversion kits for classic cars.

- 2024: Relocated the paint shop to Hindmarsh, near Adelaide CBD, as part of a new flagship branch.

Our Craftsmanship

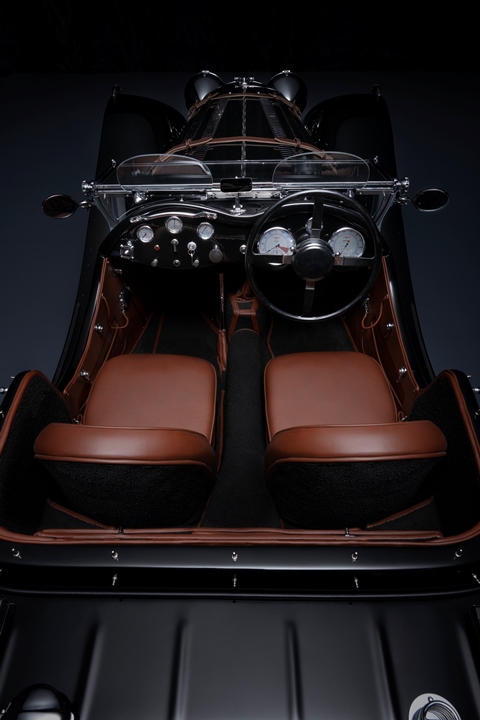

For over six decades, Finch Restorations has been synonymous with precision, artistry, and passion in classic car restoration. Our expert craftsmen seamlessly blend heritage coachbuilding techniques with modern engineering to deliver concours-level restorations that stand the test of time.

Our in-house workshops specialise in:

- Coachbuilding & Timberwork – Traditional craftsmanship for wooden-framed vehicles.

- Panel Beating & Metal Fabrication – Hand-formed precision metalwork.

- Powertrain Rebuilding – Mechanical overhauls & authentic engine restoration.

- Concours-Level Paint & Finishing – Award-winning refinishing techniques.

- 3D Scanning & Reverse Engineering – Advanced technology for precision restoration.

Global Reach & Clientele

Our reputation reaches far beyond the borders of Australia, as Finch Restorations-built classic vehicles are proudly showcased at some of the most prestigious automotive events, renowned museums, and exclusive private collections across North America, Europe, and Asia.

The exceptional craftsmanship and attention to detail exhibited in our restorations have garnered significant acclaim, with vehicles meticulously restored by our talented team winning top honours at internationally recognised events.

Notable accolades include prestigious awards at the illustrious Pebble Beach Concours d’Elegance, as well as the esteemed Greenwich Concours d’Elegance, further solidifying our position as leaders in the classic car restoration industry on a global scale.

Visit Us & Experience the Art of Restoration

We warmly invite car clubs to come and immerse themselves in the fascinating world of classic car restoration, where they can witness the intricate processes involved firsthand. Our workshops located in Mount Barker are home to an impressive collection of 40 to 50 vehicles, each at different stages of restoration, providing visitors with a rare and unique opportunity to gain insight into our meticulous and passionate approach to this craft.

We highly encourage groups to arrange a visit, as this experience promises to be both educational and engaging. Participants will have the chance to delve deep into the art of classic car restoration, learning about the various techniques, tools, and dedication that go into each project. This is not just a tour; it’s an invitation to appreciate the craftsmanship and history behind every classic vehicle we restore.

Career Opportunities

Do you have a deep-seated passion for classic cars and the intricate art of restoration craftsmanship? If you possess trade or professional qualifications specifically in the field of pre-1990s automotive restoration, we would love to hear from you.

At Finch Restorations, we are dedicated to preserving the rich history of automotive design and engineering, and we offer unique opportunities for skilled individuals like you to make a meaningful contribution. Join us in our mission to celebrate and restore these timeless vehicles, ensuring their legacy endures for future generations to appreciate.

The Legacy of Ray Finch

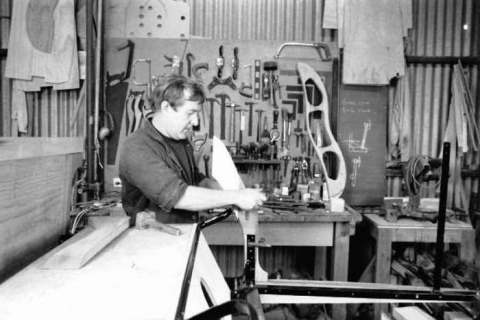

Ray Finch’s fascination with vehicles began in his early years when he meticulously restored his first classic car as a personal project. This passion soon evolved into a full-fledged business, attracting collectors and enthusiasts from across Australia and beyond.

Ray’s expertise in panel beating, coachbuilding, and mechanical engineering set Finch Restorations apart. Over the years, he built a team of highly skilled artisans, instilling a philosophy of excellence that continues to define the company today.

Ray Finch’s journey began in 1965, driven by his passion for classic cars. His expertise in panel beating, restoration, and fabrication led to the establishment of Finch Restorations, which has since become Australia's premier restoration specialist.

Finch Restorations History: Ray Finch

Finch Restorations history goes back to 1965 when Ray Finch established the business in Mount Gambier, South Australia.

Ray was born in England in 1941 and his family had migrated to Australia on the ‘SS Cameronia’ in 1951 when Ray was 10. Ray’s father had been a driver for Allards in London after the Second World War; then became works tester for the Ford Motor Co., including their classic sports cars. These inspired Ray.

After leaving school, Ray undertook an apprenticeship with the General Motors Holden dealers in Mt. Gambier. Ray started off as a motor mechanic for two years and gained a good mechanical background. Ray then transferred to the panel shop, and quickly rose to become the work foreman.

When he was 21, Ray went to New Zealand for bike racing and obtained a small contract to race there with £10 appearance money plus any winnings. As money was getting a bit short, Ray took a job at a long established company called Newton King in New Plymouth. They were importing brand-new Triumph TR3’s in ‘knock-down’ form, would put them together, paint them and finish them off.

Ray had a very good relationship with the English owner of the company. The owner told Ray that if he stayed with the company for another 12 months, he would pay all his expenses to get back to Australia. Ray obtained his first insight into coach-building at Newton King, where they made refrigerator-van bodies, and bus bodies. Here he learned to use an English Wheel metal-working machine to make corners for bus bodies. Many buses, in those days, had a wooden frame.

Ray moved back to Mt. Gambier in 1964 to work in a crash-repair and detailing shop. In 1965, Ray decided to go into business himself and established a crash-repair shop with a tow-truck on the road. Ray also joined the local Veteran and Vintage Car Club, and would do odd jobs for people. In 1966, Ray also joined another union when he married his wife.

“I could work long hours. Sometimes I would drive a tow-truck 300 miles from Mt. Gambier to Melbourne to pick up a crashed car. Once within radio distance would ring my wife to prepare breakfast then I’d go straight to the workshop to work on the vehicle I had towed.”

A few short years later, Ray received an offer from the local Ford dealers to buy his repair shop. Ray accepted, and in 1970 he bought some industrial land on the edge of Mt. Gambier, and set up an all-purpose shop to do classic car work. He was getting a lot of work from Victoria but not a lot of work in Mt. Gambier, where people did not have the money to spend. He was working by himself while employing another man part-time.

Ray and his wife moved to the Adelaide Hills in 1985. He rented a workshop shed and a house at Echunga, opposite the Golf Club. At Echunga, he met Wayne Hocking who was making excellent antique furniture. They worked together as Finch & Hocking, but they weren’t financial partners. The business grew from there, and they soon outstripped the workshop.

In the late 1980s they moved to Mt. Barker where they built a purpose-designed factory. Ray was now about 50 years old, while Wayne Hocking was about ten years younger.

In 1989, Ray advertised for a full-time employee and Colin Higgs, who had been in the industry at Woodside, replied to the advertisement and joined the company as Ray’s first employee.

Colin, who today still works for Finch Restorations, has had a good association with Ray over the years. They travelled away together on many trips, with Colin being pit crew for Ray. All the people who worked for Ray are still friends.

At Mount Barker, the business soon established an excellent reputation for building MG T-type bodies; they built over 100 bodies all told. They thought they had plenty of room at Mt. Barker, but became deluged with work. They gradually employed more and more people to work with them.

In the car world, everybody knew Ray and knew about the business. They were approached by General Motors engineers, asking them to undertake re-work on Monaros. GM’s dies and presses were misbehaving and panels were coming out the wrong shape. General Motors would send crates of panels up to the Mt Barker workshop, or employees like Colin would go down to GM’s metal shop, and with their shrinking machines re-shape the panels.

Finch Restorations were also doing work for Mitsubishi. They did a lot of colour-check cars for them, and would paint upholstery, using spray. Mitsubishi designers would say “We want this pale green or yellow in here.” Seats would be sprayed so that the designers could see what they would look like. They would be asked to cut a car down the middle, to produce a concept car that showed the motor-shaft cut down the middle.

“Blokes like me and Colin can be found overseas, but are thin on the ground in Australia. I was probably first to do this as a specialist business in South Australia. Some crash repair shops might paint up a car and sell it as a restoration … but its not. Most people who do this would be a hobbyist.

“The history of the business … it just evolved, became bigger and bigger and we earned a reputation for good work.”